Fundamental Science of Robust Membrane Manufacturing

Fig. 4.1. GAP C will use UMCP (Universal Membrane Chemistry Platform) materials to co-designing mechanically robust, permeable, selective membranes for filtering aqueous solutions of MFP (Model Fluid Platform) components. Via systematic experimental and theoretical studies, we will identify the scientific fundamentals underpinning the creation of robust isoporous membranes, gaining rational control over the SNIPS (non-solvent induced phase separation (NIPS) with self-assembly) process to radically transform membrane manufacturing.

GAP Co-Leaders

-

Gabriel Sanoja Lopez

GAP C Co-Leader

-

Glenn Fredrickson

GAP C Co-Leader

GAP Co-Investigators

-

Berkin Dortdivanlioglu

GAP C Co-Investigator

-

Benny Freeman

Director

GAP B Co-Leader

GAP C Co-Investigator

-

Venkat Ganesan

GAP B Co-Investigator

GAP C Co-Investigator

-

Lynn Katz

Associate Director

GAP A Co-Leader

GAP B Co-Investigator

GAP C Co-Investigator,

IF Co-Investigator

-

Nate Lynd

GAP A Co-Investigator

GAP C Co-Investigator

IF Co-Leader

-

Todd Squires

IF Co-Investigator

-

Greg Su

GAP A Co-Investigator

GAP C Co-Investigator

IF Co-Investigator

Problem Statement

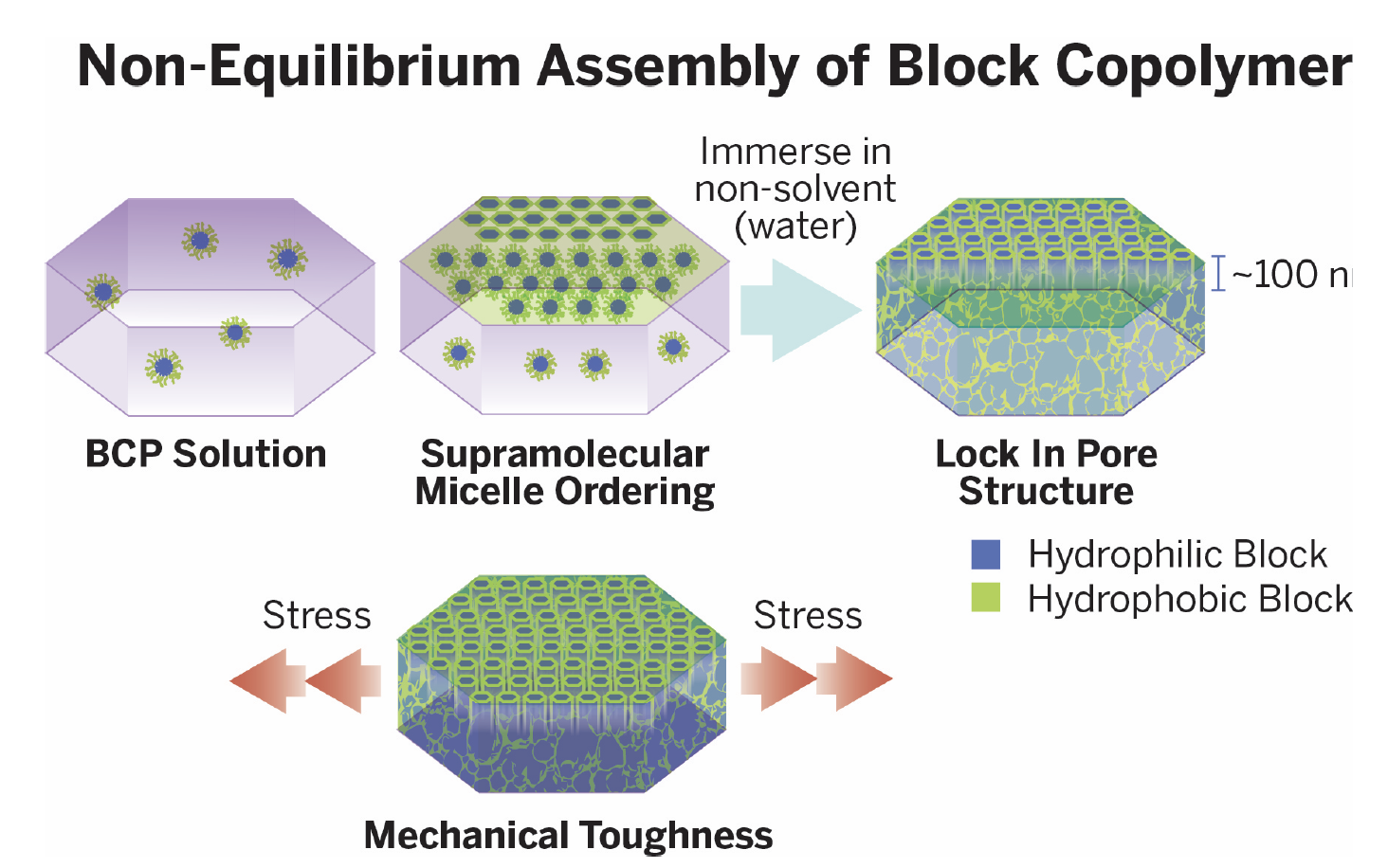

As shown in Fig 4.1 (above), GAP C will develop the fundamental knowledge of materials and process science to enable the large-scale manufacture of mechanically durable, high-performance membranes for ultra and nano-filtration of water. Non-solvent induced phase separation (NIPS) is the predominant commercial method to manufacture porous polymer membranes that are thin (i.e., high flux) and selective. In this process, a non-solvent (usually water) is contacted with a film of polymer dissolved in a good (organic) solvent. As the non-solvent diffuses into the film and the good solvent diffuses out, the polymer phase precipitates and ultimately vitrifies, leaving a water-filled pore structure in the wake of the vitrification front. In spite of decades of investigation, NIPS processes are conducted as “black box” operations with little understanding of the farfrom- equilibrium physics connecting process and formulation inputs with membrane microstructure and performance. It is therefore difficult to improve upon the current state of the art and evolve membrane performance to optimal levels of flux and selectivity. NIPS membranes for ultra and nano-filtration typically have one polymer component, usually a polysulfone or poly(vinylidene fluoride) homopolymer, and an asymmetric structure comprised of a gradient in pore sizes across the membrane. The surface layer of the membrane with the smallest pores provides all the selectivity and most of the hydrodynamic resistance to water flow, while the remainder of the membrane primarily serves as mechanical support. Such membranes have the mechanical strength to survive long-duration commercial separations, while offering a reasonable compromise of water permeance against solute size selectivity.

Emerging research on a process that substitutes the homopolymer with a block copolymer, so-called SNIPS (NIPS with self-assembly), has shown considerable promise in creating membranes with dramatically improved flux and selectivity. Well-orchestrated SNIPS membranes have an underlying gradient pore structure like that of NIPS, but a better-organized surface layer (i.e., skin) with a narrow pore size distribution centered in the 10 nm scale range. The high degree of order in the skin arises from microphase separation of the block copolymer. Such “isoporous” membranes break the traditional inverse relationship between flux and selectivity and represent a major opportunity for improvements in membrane performance and the energy efficiency of water purification. To date, SNIPS has been demonstrated on a narrow class of amphiphilic diblock copolymers, generally involving hydrophobic polystyrene (PS) and short hydrophilic poly(4-vinyl pyridine) (P4VP) blocks (i.e., PS-b-P4VP). In SNIPS membranes prepared from casting solutions with solvents favoring the hydrophobic PS block, the short hydrophilic P4VP block lines the pore walls in the skin layer, while the longer PS block forms the inter-pore matrix. Solvents and casting conditions necessary to achieve isoporous membrane structures have been optimized for this specific system, but the resulting membranes are brittle and unsuitable for commercial applications. While the inclusion of rubbery blocks has revolutionized the design of tough thermoplastic elastomers via block copolymer self-assembly, analogous fundamental design rules for toughening porous SNIPS membranes do not exist nor is there a set of design rules that allow efficient navigation of the vast design space to create isoporous, tough membranes.

GAP C will remedy this problem by developing the scientific understanding necessary for SNIPS-based manufacturing of high-performance membranes from universal membrane chemistry platform (UMCP) amphiphilic block copolymers with optimal flux, selectivity, and mechanical properties. GAP C will both develop fundamental understanding of the role of compliant blocks and pores on membrane toughness and crack propagation in order. Further, a new physics-based model of the non-equilibrium SNIPS process will guide the identification of optimal solvents and casting conditions, as well as provide a fundamental understanding regarding the interplay of multi-component diffusion, thermodynamics, self-assembly, polymer entanglement, and vitrification in establishing membrane structure. Altogether, the knowledge gained by GAP C has the potential to enable the large scale manufacture and commercial deployment of polymer membranes with unprecedented separation performance.

The fundamental science questions on isoporous membranes that GAP C will tackle are aligned with the DOE’s Grand Challenges for Basic Energy Sciences, in particular “How do we characterize and control matter away– especially very far away –from equilibrium?” and the Transformative Opportunities for Discovery Science, e.g., “Mastering Hierarchical Architectures and Beyond-Equilibrium Matter.” GAP C is uniquely suited to address the fundamental science of manufacturing, and targets priority research directions of the Transformative Manufacturing BRN, including to “achieve precise, scalable synthesis and processing of atomic-scale building blocks for components and systems,” and “unravel the fundamentals of manufacturing processes through innovations in operando characterization.”

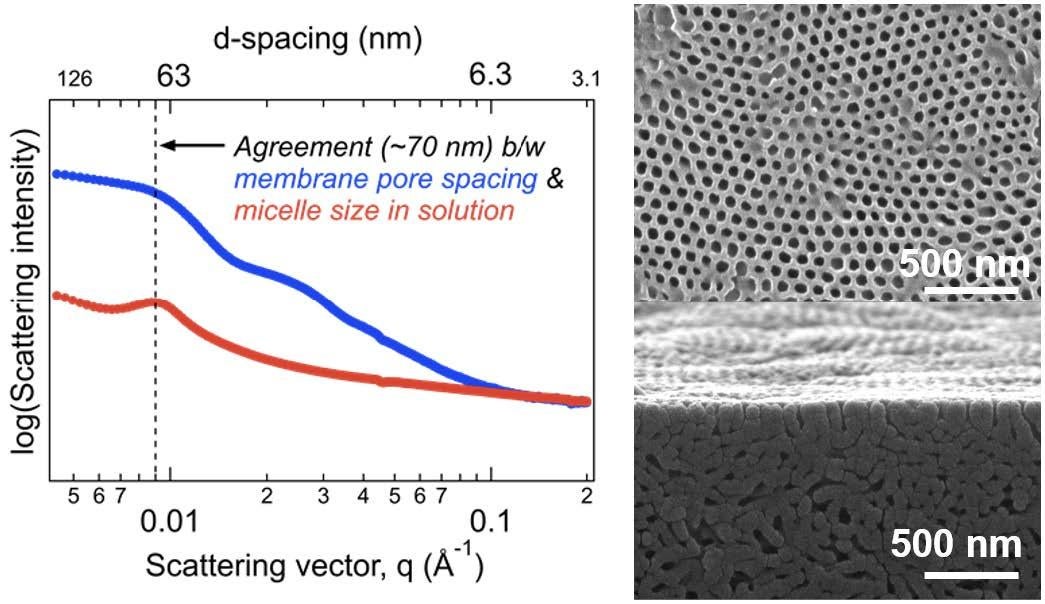

Fig. 4.2. Surface (top) and cross-sectional (bottom) SEM images of an M-WET isoporous membrane prepared via self-assembly + aqueous nonsolvent-induced phase separation (NIPS) from a casting solution of 13 wt. % PSb-P4VP dissolved in a 1:1:1 blend of N,Ndimethyl- formamide, 1,4-dioxane, and tetrahydrofuran. This membrane was prepared with a 20s dry step at 50% relative humidity. Agreement in length scales obtained from SAXS profiles of the micellar casting solution and the final membrane highlight M-WET’s ability to control pore size of SNIPS membranes through directed self-assembly of PS-P4VP micelles in casting solutions.

Research Questions

How do we design and synthesize UMCP polymers that are suitable for SNIPS casting into tough/strong isoporous membranes?

How do we identify scalable, translatable manufacturing processes that can be rapidly adapted to different membrane chemistries?

How do we manage the vast design space of polymer, solvent, and process variables to identify casting conditions that lead to isoporous membranes?

What is the role of pores and hierarchical pore structure on the mechanical properties of membranes?

Research Approach

The GAP C research is divided into three efforts:

Project 1, which integrates modeling and experiment to identify polymers, casting solvents, and conditions that produce isoporous membrane structures;

Project 2, which applies advanced characterization techniques to monitor the in situ formation of hierarchical membrane structure during SNIPS and in operando structure and transport characteristics of the finished membrane; and

Project 3, which seeks to understand how the mechanical properties of membranes are connected to hierarchical pore structure, and to variations in polymer chemistry, architecture, and process conditions.