IF, Project 1: Synthesis and scale-up of UMCP materials

The original porous UMCP platform has evolved into a more mechanically robust construct, with a molecular architecture optimized for improved mechanical strength and non-equilibrium processing into isoporous morphologies. We use controlled anionic polymerization techniques to create a polystyrene-bpoly(ethylene-alt-propylene)-b-poly(styrene)-b-poly[(ethylene oxide)-co-(allyl glycidyl ether)] (PS1-b- PEP-b-PS2-b-P(EO-co-AGE)) material that exhibits substantially improved mechanical properties, referenced earlier in Fig. 1.2. We refer to the blocks sequentially as S1, EP, S2, and OX. Each component has a distinct purpose, with S1 (e.g., styrene) providing a molecular anchor, EP (e.g., ethylene/propylene) inserting toughness and strength, S2 (e.g., styrene) providing the requisite modulus to maintain a nanoscopic pore, and OX creating controlled hydrophilicity channels and functionality to attach interactants. Similarly, we have developed within M-WET a second non-porous UMCP platform based on copolymers of poly(ethylene glycol) acrylates and pentafluorophenyl acrylate (PFPA) that can be functionalized postpolymerization by a wide variety of functional groups (FGs). Each GAP addresses different portions of the UMCP architectures: GAP A focuses on understanding the role of FGs on controlling water dynamics and solute interactions, GAP B focuses on the fundamentals of designing new membrane materials for selectivity by incorporating specific bonds, and GAP C focuses on the S1-EP-S2 sub-architecture.

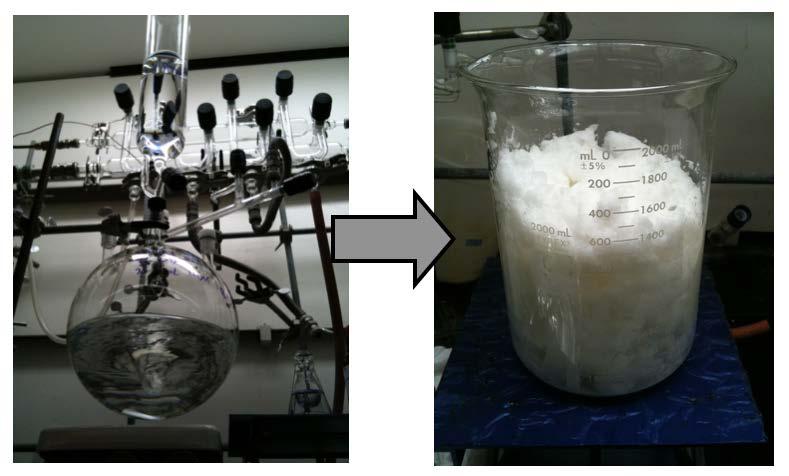

Syntheses of new UMCP variants will be performed by a Polymer Synthesis Scientist (Louise Kuehster) supervised by Lynd and Page at UT Austin using anionic and catalytic polymerization of vinyl and epoxide monomers for the porous platform and free radical routes for the non porous platform. A part-time project scientist at UCSB (supervised by Segalman and Hawker) will focus on the functionalization of both porous and nonporous UMCP materials. A specialized array of reactor glassware is available and tailored to scale-up to a 100–1000 g scale (Fig. 5.2). Materials will be synthesized, precipitated, dried, and placed in cold storage, then characterized within Project 3 for all parameters that affect processing and morphology, including overall molecular weight, molecular weight distribution, size of each block (S1, EP, S2, OX), and functional group (FG) identity. The molecular and morphological parameters will be stored in a database and made accessible to co-workers in all GAPs so that materials may be requested based on molecular and morphological characteristics, such as composition, molecular weight, pore size, spacing, morphology, and pore-size distribution, as described in our Data Management Plan.

Fig 5.2. Large-scale (8L) reactor (left) and resultant unpurified polymer material (right).